Functional Requirements:

Half of the project must be termoformed and the other half must be urethane cast

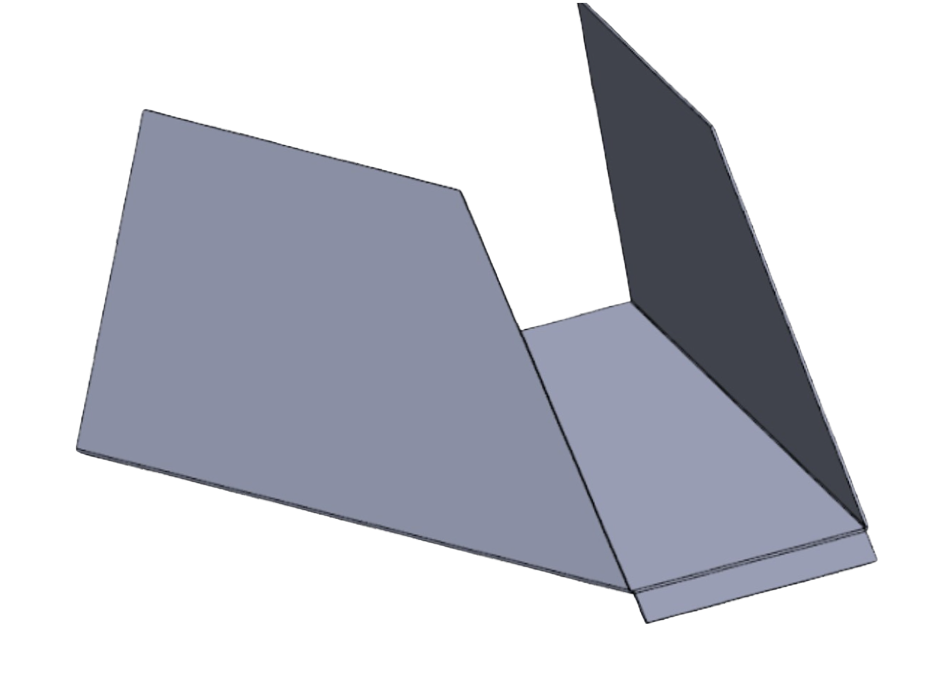

Height and angles of the thermoformed piece must be under 5in tall and 5° draft angle

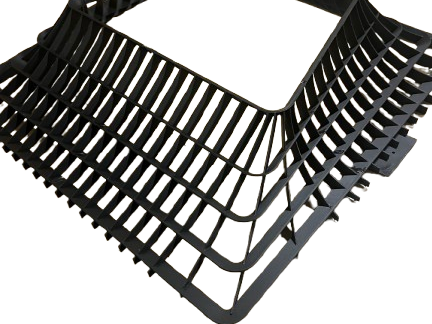

The product will have an aesthetic embossed design on both parts

The pieces fit together in a way that is secure and aesthetically pleasing

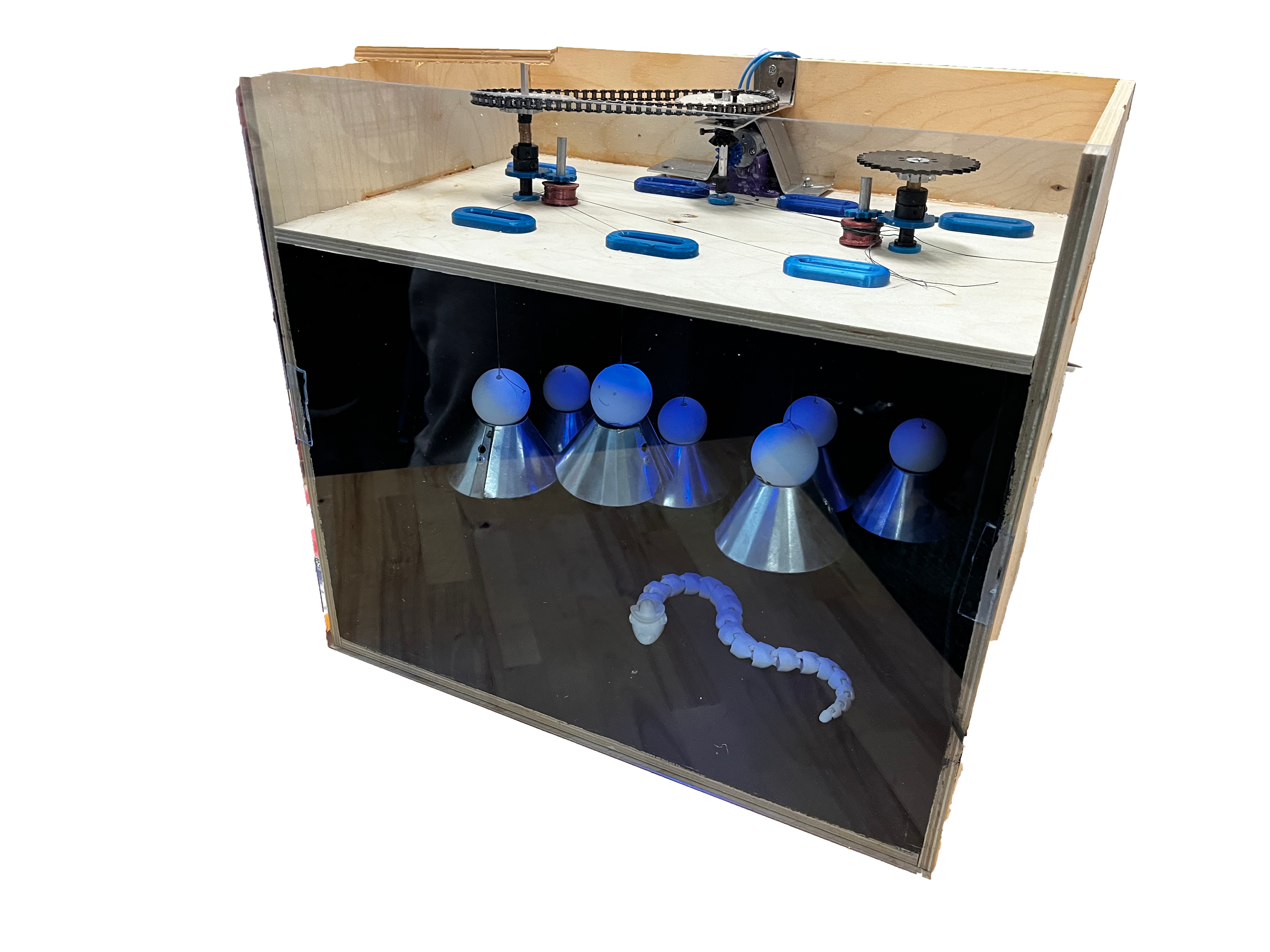

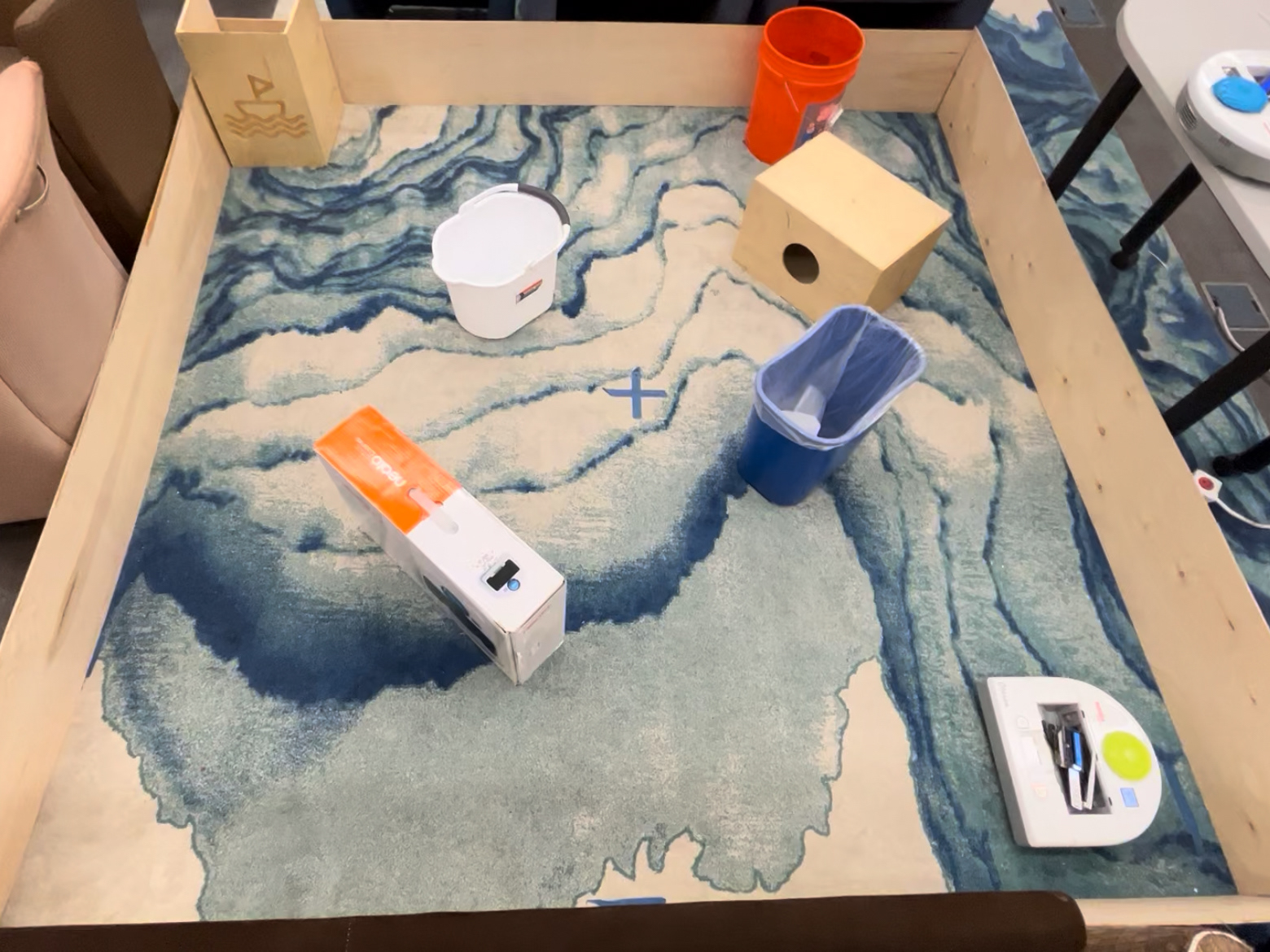

The product performs as a terrarium

This terrarium met its functional requirements successfully, as the bell jar (made by me) and the planter (made by parter) both have an aesthetically embossed aspect to improve aesthetics. The two pieces fit together aesthetically and serve as a planter; however, the system is not as airtight as a terrarium and is not a closed system.

Throughout this project, I have developed my skills in Stratasys printing, thermoforming, and understanding urethane casting. I developed a deep understanding of how to design for thermoforming and how to avoid issues with plastic not being removable from the 3D-printed mold.

Challenges I encountered during this project included overhangs in the embossed roses on the dome, which made it difficult to remove the PET-G from the 3D print. The print was also not entirely hollow and had a false floor, which made it harder to introduce compressed air to the system to remove the plastic. To fix this issue, I had to break the false floor to shoot compressed air directly between the ASA and PET-G.

If this product were outsourced to a manufacturing company in the United States, the initial cost (printing mold, creating silicone mold for urethane, smoothing print, etc.) would be high due to labor cost–estimated to be $25/hr–and time taken to let the molds and prints set. After the initial setup, however, each part would take approximately 1 hour to make.