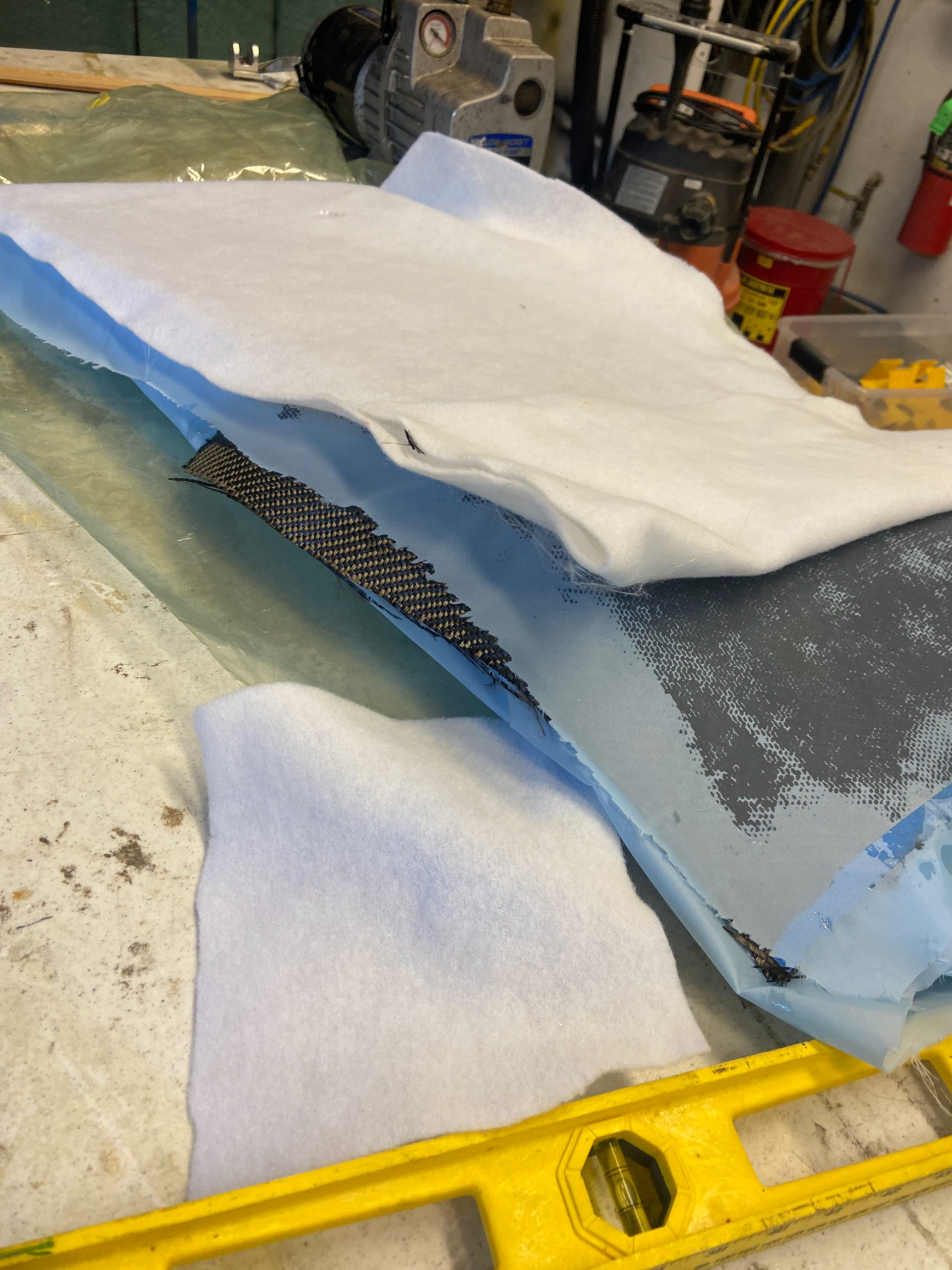

Our Baja off-road vehicle is subjected to extreme conditions, demanding robustness without compromising performance. One crucial aspect contributing to durability and agility is the construction of body panels. Here, I explored how the integration of carbon fiber composites elevates the off-road driving experience. Having carbon fiber body panels benefits the car because, compared to previous years' Baja car's use of ABS plastic, carbon fiber composites allow for customizability, strength, and ease of fabrication. Composites are significantly stronger than ABS, as they do not dent as easily, keeping the driver safe; they are easy and fast to fabricate using minimal shop resources and can be made using different molds to suit the needs of the car.

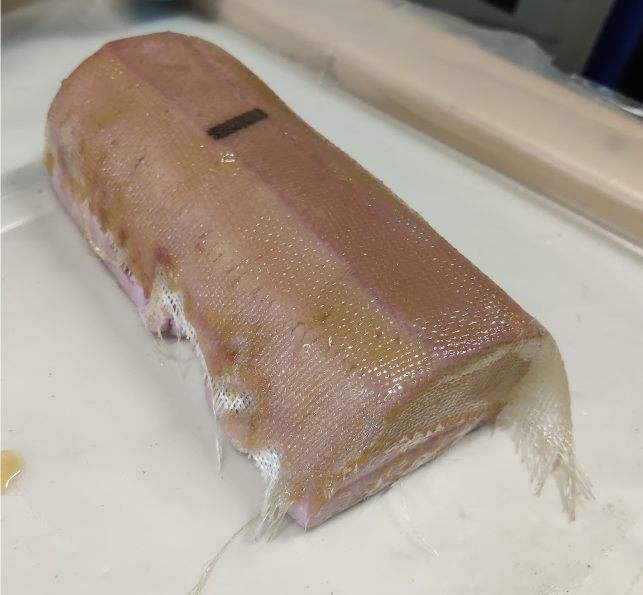

The challenge of using carbon fiber composites is finding the most effective and efficient way of molding them. Here, I tested multiple different techniques of epoxy resin and vacuum sealing to find out how to speed up the process. The other challenge with using carbon fiber in composites is that carbon fiber is a carcinogen when inhaled. Therefore, the composites must not be cut, drilled, or otherwise modified in a way where the particles of the material will enter the person's lungs. To overcome this, the Baja team has set a strict set of rules to follow when cutting or drilling the material. This includes a well-ventilated area and the use of N-95 masks.