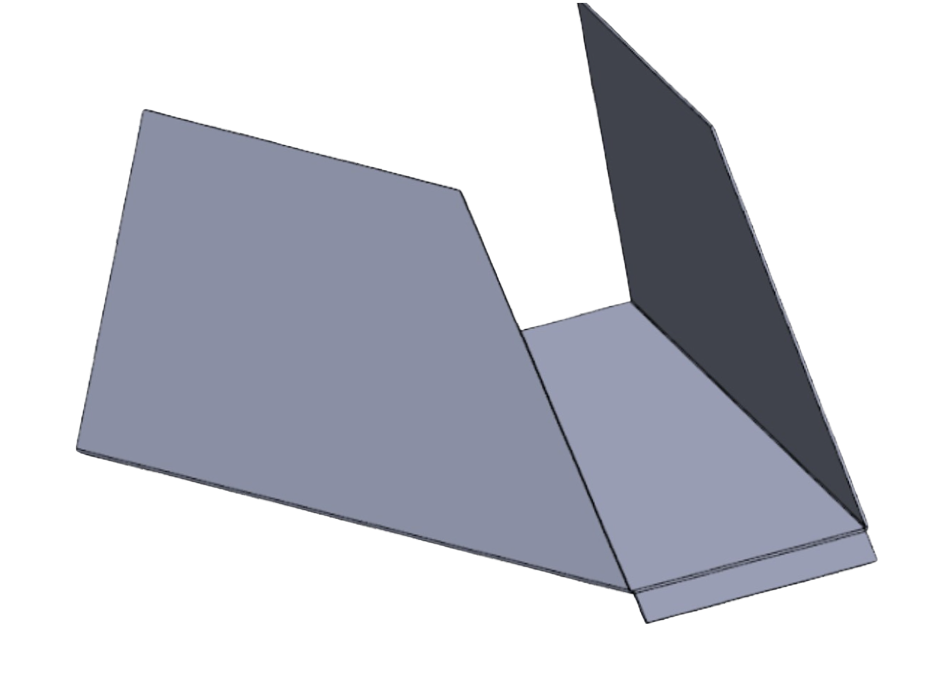

During my internship at Cala Systems in the summer of 2025, I designed an airflow system for a heat pump water heater to optimize airflow and noise performance. This grate was designed for airflow testing of the product. The end goal of this testing process was to determine the most effective and efficient way to direct airflow from the heat pump's intake to its output. There were no COTS (commercial off-the-shelf) products that met our size and shape requirements and would be effective for directing flow.

The process of designing this piece required research of COTS products and how they direct airflow through evaporator/fan systems. Computational fluid dynamics showed an uneven airflow distribution in the system and indicated that more airflow should be directed to the bottom of the evaporator. For this reason, I designed the part as a trapezoidal shape to increase airflow to the bottom (wider end) of the grate.

Testing and CFD results show that this air grate was extremely effective at improving airflow quality and reducing noise for the client. As air was directed smoothly through the evaporator, excess air was not trapped in pockets of the heat pump system, thereby reducing the noise the water heater produced.