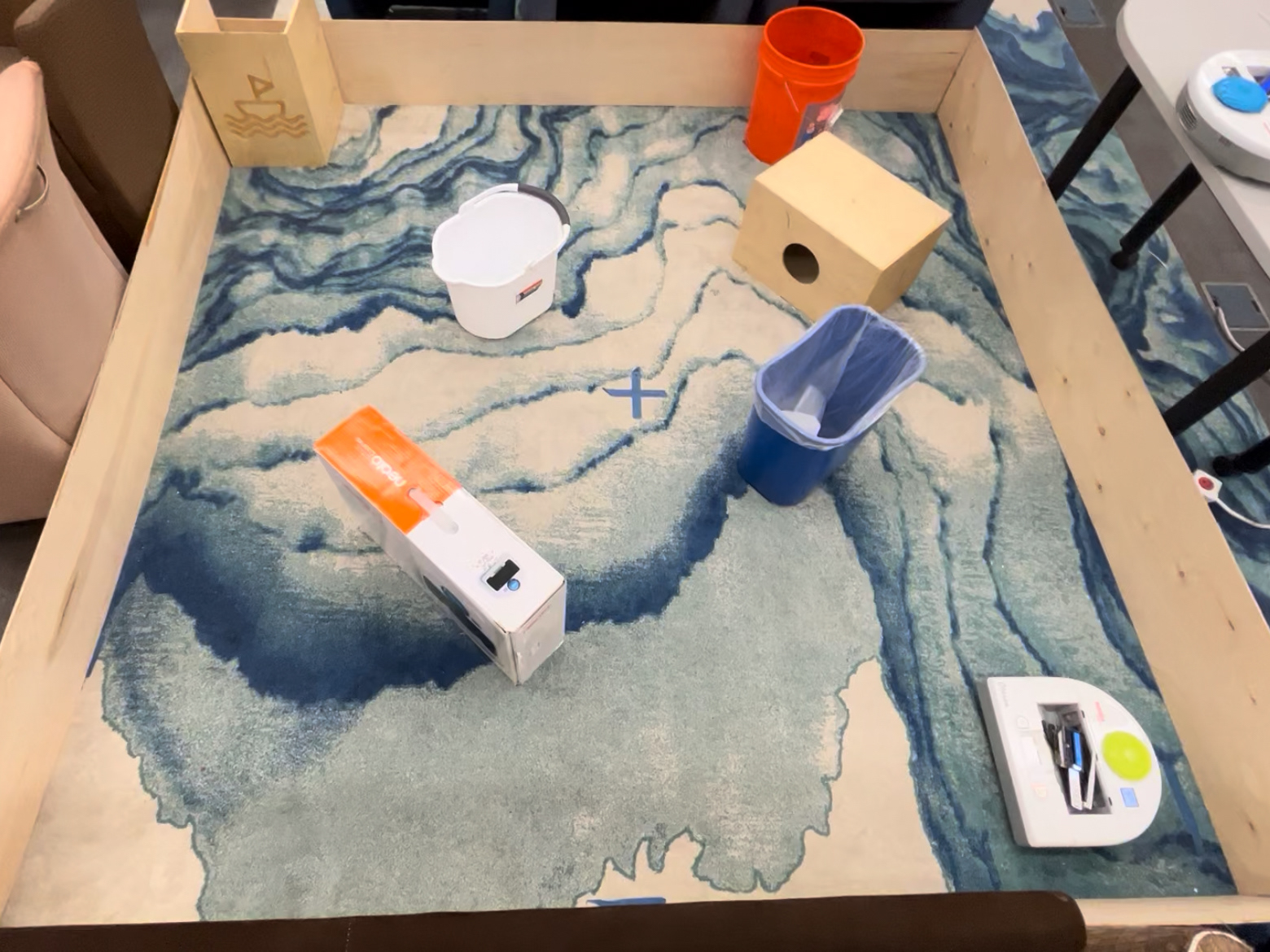

I worked with three students to create a chain-driven sculpture composed of four unique mechanical elements. We chose for our design to revolve around jellyfish in an aquarium. The mechanism I concentrated on in this sculpture was a pulley system that would move two sets of jellyfish vertically at offset times.

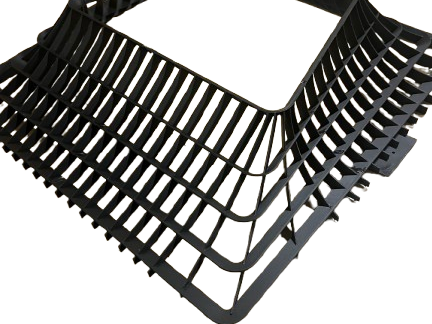

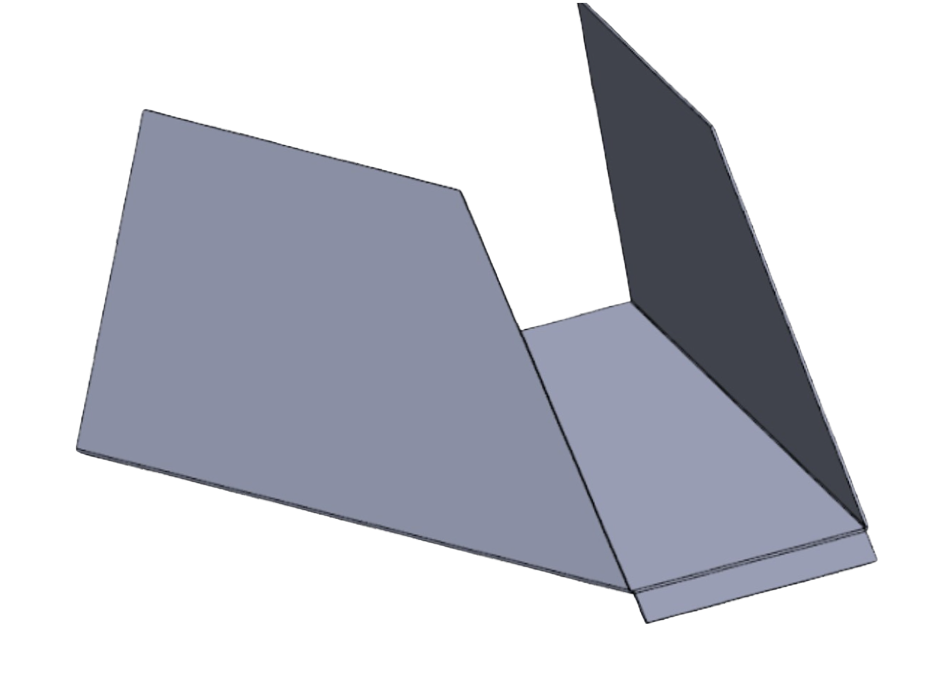

Since all of our mechanisms heavily relied on each other, my team and I worked closely together to design a chain-driven bevel gear, partial gear, and pulley system using SolidWorks and GrabCAD. The bevel gear translated the motor’s vertical rotation to horizontal rotation for the chain to drive the partial gears. The partial gears were attached to the pulleys, triggering them to rotate for half of the gear’s cycle before release, dropping the jellyfish.

I lead the assembly for this sculpture. I used a CNC router to fabricate the housing and a 3D printer for the pulley. The jellyfish were attached to the pulleys using a fishing line. The pulleys had a socket for the fishing line, and then the wire was secured using super glue. Additionally, I taught my teammates how to assemble a chain drive, as I was the only team member with prior experience in the area.